全国服务热线

全国服务热线

DATE:2021-06-28

SOURCE:http://www.wtforging.com/en/supply/jcmdj/74.html

13301512601

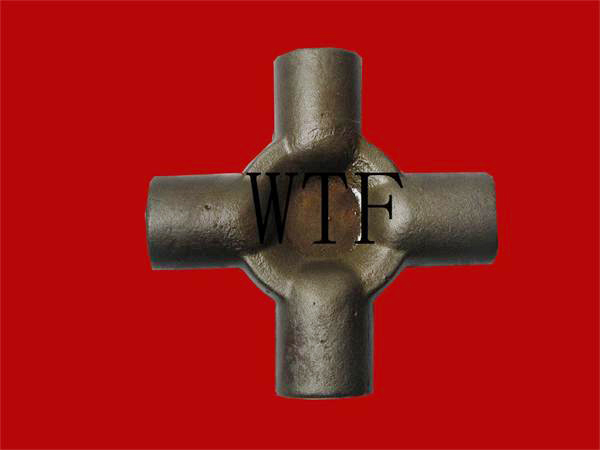

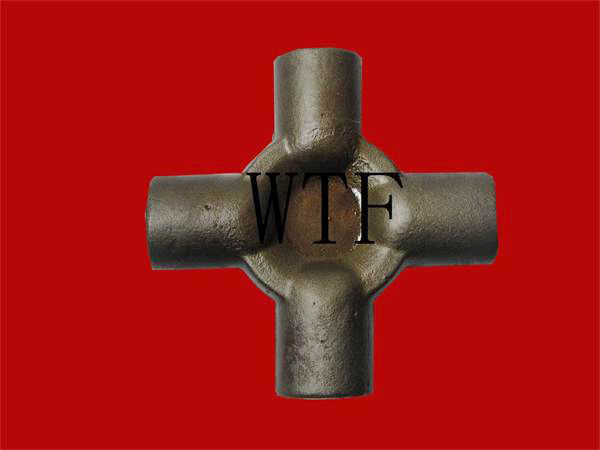

The cross shaft die forging manufacturer selects the die forging process to obtain the die forgings with acceptable overall dimensions, internal structure and performance. Therefore, the corresponding quality inspection must be carried out according to the requirements of the technical conditions of die forgings. In fact, the quality inspection of die forging products is not only the final inspection in front of the factory, but also the further scientific management and use of all quality inspection data to continuously improve the production process and improve the production level of the enterprise.

What items are included in the quality inspection of die forgings?

The quality inspection of die forgings is divided into two parts: appearance quality inspection and internal quality inspection. Each part includes many inspection items. One is chemical composition inspection, which is usually sampling and analysis in front of the furnace during the smelting process. Especially for important or suspicious die forgings, some fragments can be cut from the forgings, and chemical analysis or spectral analysis can be used to check the chemical composition.

Surface flaw detection is also a part of the quality inspection of die forgings. The acid and alkali surface quality of the film is judged by magnetic particle testing and fluorescence testing. In addition, there are ultrasonic inspection, macroscopic structure inspection, microscopic inspection, residual stress inspection, etc., all of which should not be ignored.