全国服务热线

全国服务热线

DATE:2021-06-26

SOURCE:http://www.wtforging.com/en/supply/jcmdj/72.html

13301512601

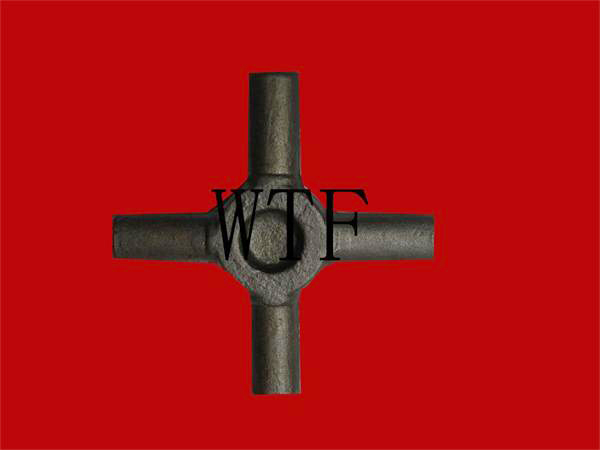

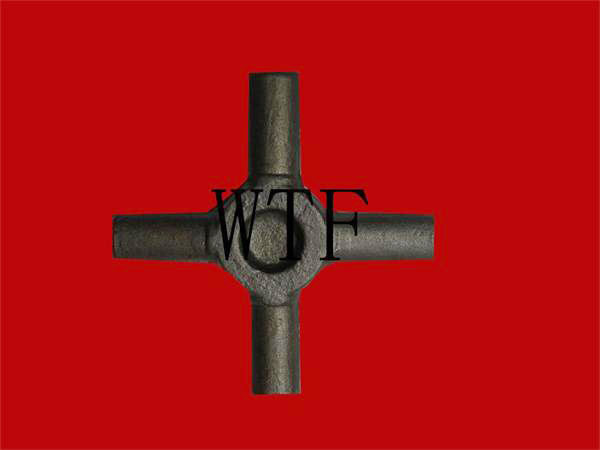

In the production process of cross shaft die forgings, several parameters must be strictly controlled. If there is any error, the surface of die forgings will have defects. When observing the quality of die forgings, it can be found that the most common defects are cracks, which are also divided into transverse cracks and longitudinal cracks. For die forgings, the causes are different. Through the understanding of the transverse cracks on the surface of die forgings, although these cracks are deep and shallow, the causes of formation are also different.

During the forging process, the alloy forging die-casting blank was pre-extruded, and the effect of extrusion pre-deformation on the die structure and mechanical properties was studied. Therefore, the aging phenomenon of the die forgings was caused. The continuous precipitation stage was mainly at the grain boundary, and the direct aging of the forged ingot phase was mainly due to the discontinuous precipitation of a large number of lamellae in the product. After the pre-deformation by extrusion, the forged parts were directly compared with the ingot, The performance of die forgings has been significantly improved, and the change of performance is very superior, so the brittle fracture is significantly reduced.