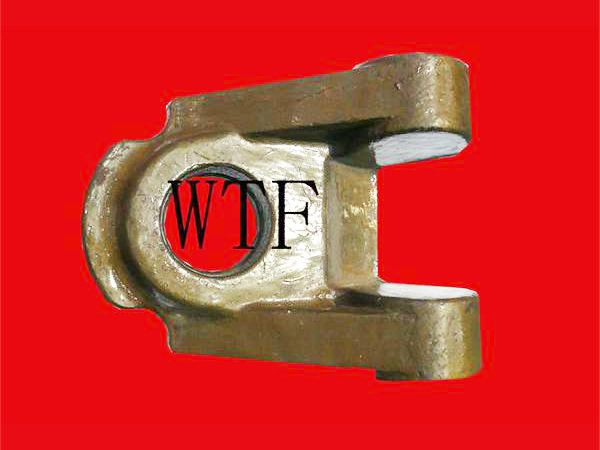

The production of precision industry should be very careful. If the whole precision equipment cannot be used due to the small differences in precision parts, the cost loss will be very large. Therefore, when processing precision parts, the general manufacturers will use die forgings to assist in production. For example, the industrial robot block forging is one of many die forgings, What about the cracks in the block forgings of such industrial robots during production and processing? Let's take a look.

Due to the research on the microstructure effect of heat treatment in the alloy industry robot stop forging system, the software optical microscope and the image using the hot forging method understand that its characteristics are that the temperature of the heated billet exceeds the phase change point and the mold temperature is lower than the phase change point, and the microstructure of the hot die forging lacks uniformity, which is caused by the phase change and uneven deformation during the deformation process, The heat treatment system cannot completely remove the inhomogeneity of the microstructure of alloy die forgings.

However, with the extension of the high temperature holding time, the irregularity of the industrial robot block forgings decreases. In the case of double heat treatment, the cooling speed after heat treatment is slower. In addition to the transverse surface cracks, the transverse cracks can also occur in the die forgings, because the cold ingot is heated too fast in the low temperature zone during the forging process or the tension caused by the center, or the plasticity of high carbon steel and high alloy steel is poor, It is caused by too little power in forging operation.

What should I do if there are cracks on the forging surface of the industrial robot block?

In addition to the surface and internal surface, there are also different defects. The longitudinal cracks in the forging surface exist in an extension or disturbance, or in the center of the peak near the cap, which is used to form the mold and the inner wall of the new defect. The main reason for the latter is that the shrinkage of the orifice will not be concentrated in the part of the ingot cooling cover, In addition, the amount at the cutting end of the die forging is too small, so there is secondary shrinkage of the hole or residual shrinkage hole near the blank mouth end. In addition, the internal longitudinal crack forging is caused by the tension of the central part of the equipment.

Due to the reasonable distribution of metal wires, the yield potential of metal materials can be amplified. Therefore, when important parts of die forgings are used, strict requirements are imposed on the metal flow lines. Through understanding the hot forging process of the aerodynamic distribution part, the design process of improvement measures is proposed. As the aluminum alloy support gasket is used as the support wing of the aircraft, the important parts of the bearing must be closed to improve the mechanical performance of corrosion resistance and fatigue resistance.

It is inevitable that various problems will occur in the processing of industrial production. This is a common phenomenon in production and processing. There are no more good methods except to pay more attention during processing. The cracks on the surface of the industrial robot block forging are caused by problems in the production heating treatment system. If you can find and handle them by driving, you can reduce the loss of products as much as possible. If the forging of the stop block of the industrial robot has cracks, relevant methods can be adopted for repair.

全国服务热线

全国服务热线